Battery

UNITECH, a total solution provider in battery module

related adhesives, surpasses the limit of battery technology development.

Overview of Battery Business

Various technological evolutions occur in the process of transitioning from combustion automobiles to electric vehicles.

To overcome various issues and limitations that occur in improving battery technology, UNITECH solution support customers in challenging these issues. Active design is promoted to overcome the technical limitations for enabling the new solution to secure better marketability for expansion and supply.

UNITECH provides better values by supplying products that can be easily understood even by customers who aren’t chemical product specialists and helping with the designs.

Battery Solution

Technology that overcomes the limits of electric vehicles

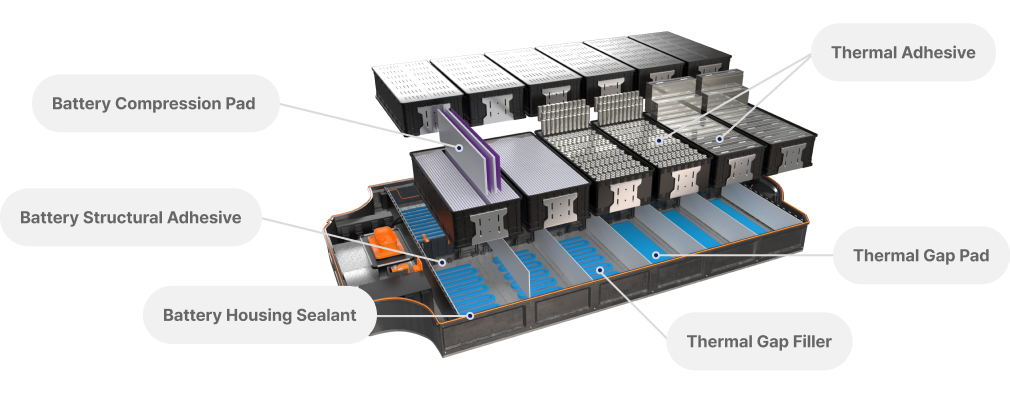

-

- Structural adhesive for the dissimilar materials

- Limitation of material selection is reduced, and stability is increased

-

- Battery compression pad

- Consistent surface pressure is provided to maximize the battery durability

-

- Thermal adhesive and gap filler

- Battery and system heating is relieved effectively

-

- Potting material

- Module and system are protected from the external environment such as humidity, temperature and vibration, etc

-

- Thermal pad

- Applicable without the automatic application system

-

- Sealant

- Exclusively for the battery module protecting the system from dust and moisture

Battery technology & application field

-

Heat control of ESS, battery module adhesion and heat control system

-

Overall battery system module and pack of the electric and hybrid vehicles

Product

-

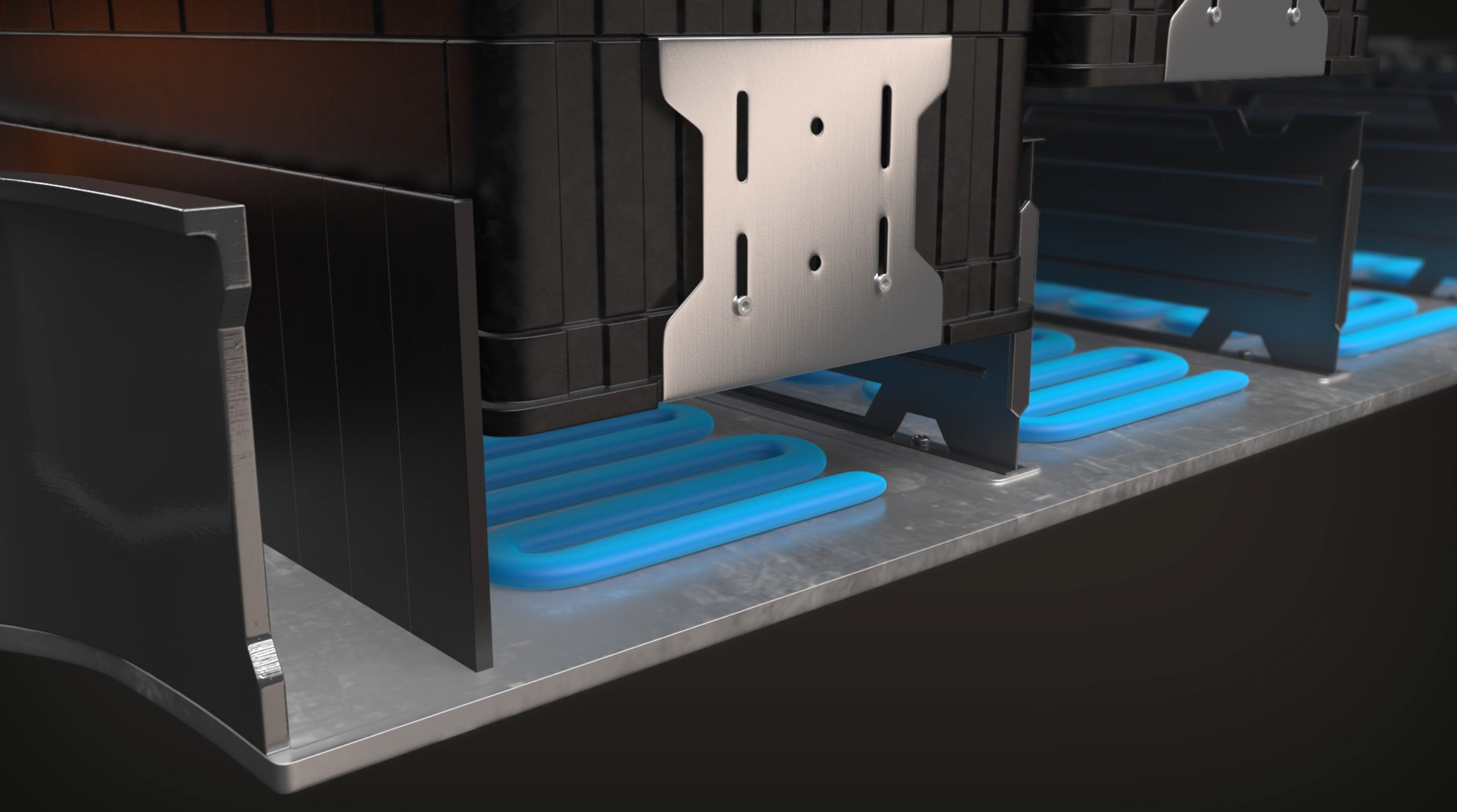

Thermal adhesive

UniCore® thermal adhesive uses various special chemical solutions to efficiently solve the heat generation issue of the battery system while realizing superior adhesiveness and durability at the same time.

- Product characteristics

- Based on the top adhesive technology, mechanical and chemical adhesive performance of various materials are maximized

- Various filler composition capability for realizing efficient thermal conductivity performance

- Outstanding durability, maintaining the initial performance despite the extreme environmental conditions and long usage life

- Information description

-

DescriptionProduct realizing both the adhesive and thermal performances

-

UseApply to all parts requiring adhesion with heating components and other components, as well as areas requiring thermal conductivity

-

Application areasBetween the bottom of the vehicle battery module and cooling system, or between similar electronic components

-

Main propertiesShearing strength, tensile strength, thermal conductivity and hardness, etc.

-

CharacteristicsAs the 1~2K liquid type such as polyurethane, epoxy and silicone, etc., both manual or automatic robot work is possible. Room-temperature or high-temperature setting product

-

Brand

-

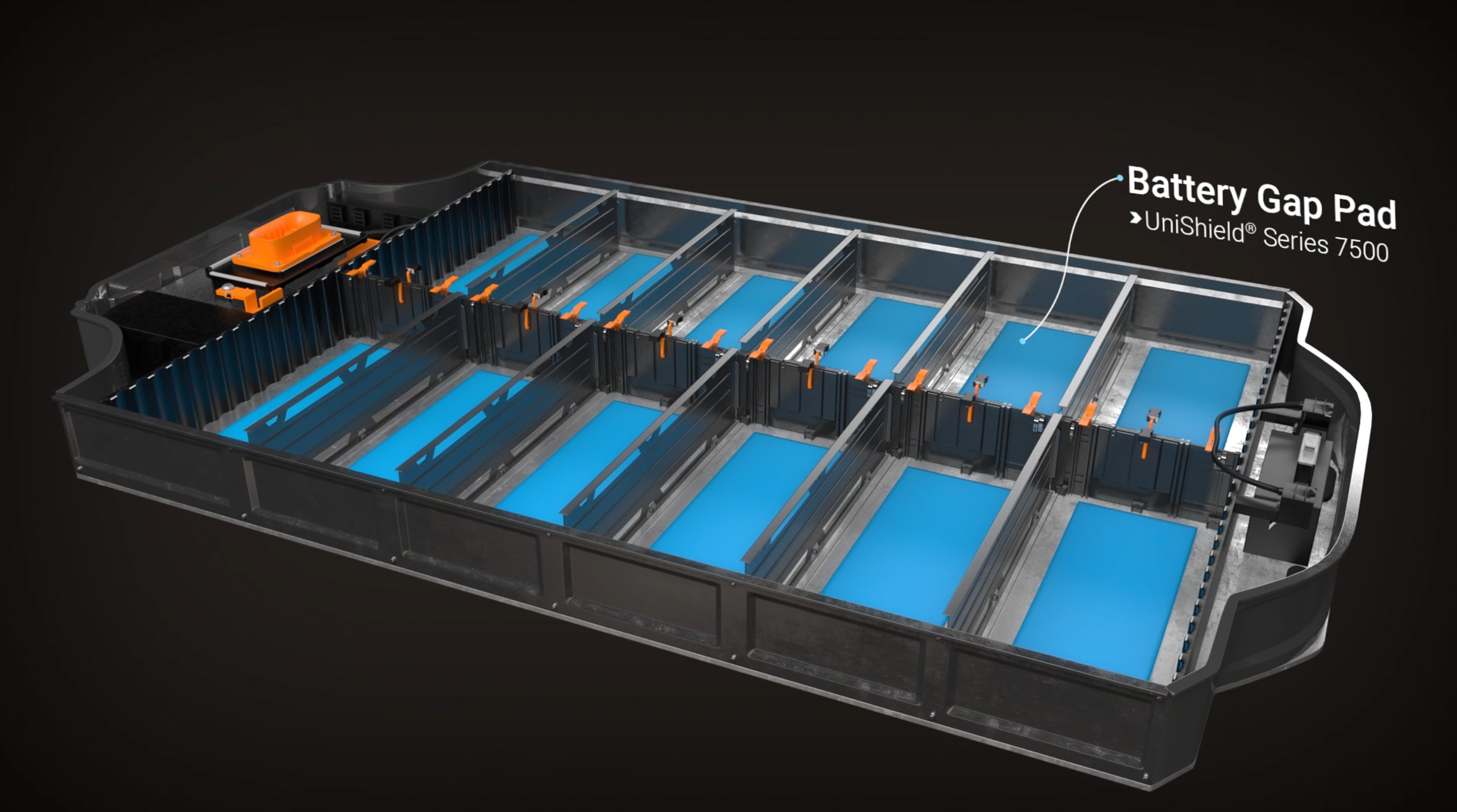

Thermal Gap Pad

UniShield® Thermal Gap Pad improves the freedom of thermal system designs based on the product groups of various thermal conductivity and hardness

- Product characteristics

- Product group applied with technologies that may be suitable for various battery use conditions such as thermal conductivity and shock mitigation, etc.

- Available for use in the overall electronics field by preventing oil bleeding

- Automated production line guaranteeing uniform quality

- Information description

-

DescriptionA pad manufactured based on silicone resin, for the purpose of thermal conductivity on the heat-generating and cooling parts

-

UseThe purpose is to increase the physical contact section with the cooling system to lower the temperature of the heat-generating components in the electronic device

-

Application areasBetween the battery module and cooling parts in the electric vehicle

-

Main propertiesThermal conductivity, hardness and specific gravity, etc.

-

CharacteristicsSilicone, pad type, manual work or partial automation

-

Brand

-

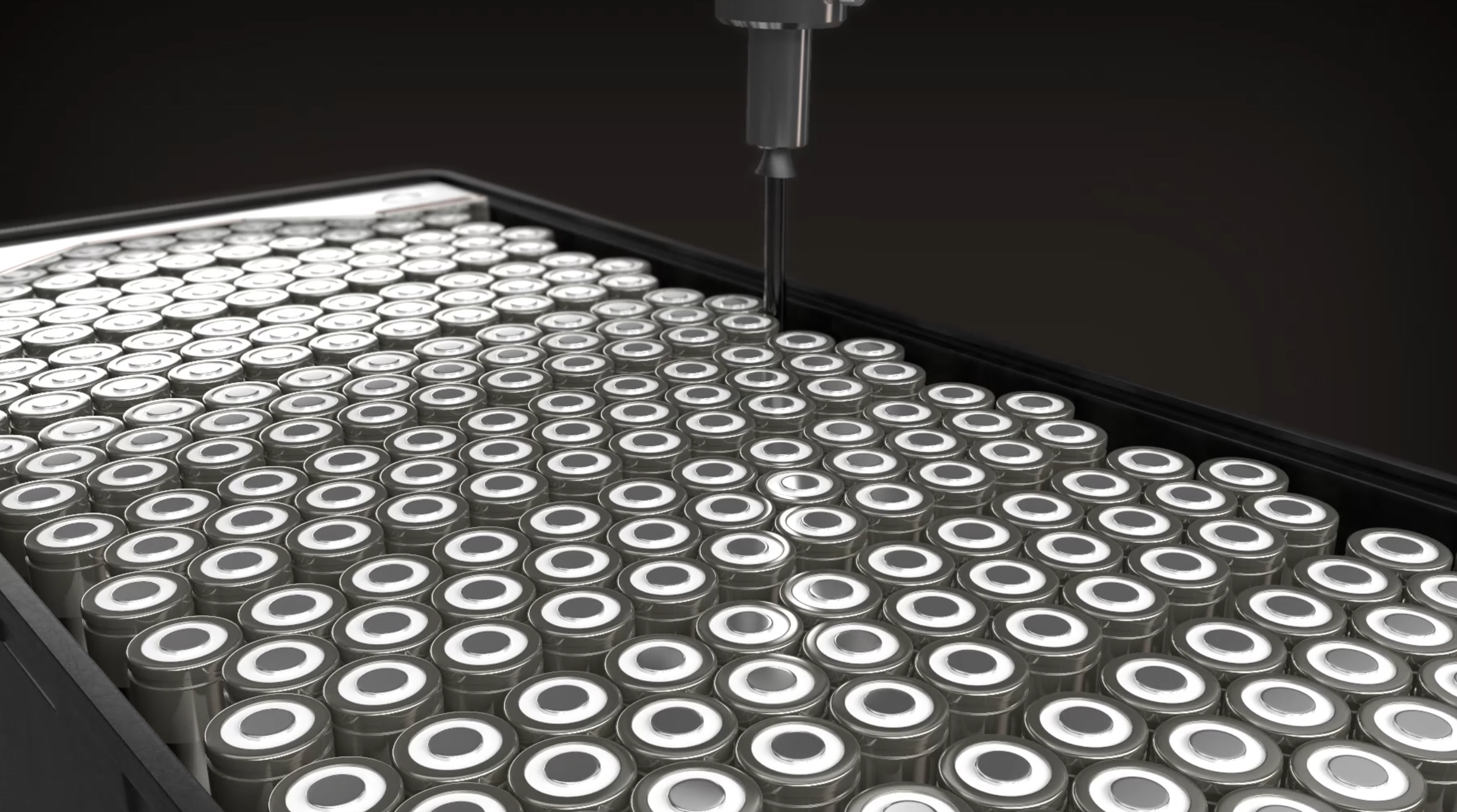

Thermal Gap Filler

UniShield® Thermal Gap Filler adds value to the customer efficiency and design stability based on the outstanding workability and durability that are optimized for the automation process.

- Product characteristics

- Performance and price are simultaneously satisfied by optimizing the filler composition

- Stable applicability based on the mix engineering capability that was accumulated for 20 years

- Long-term environmental test capability exceeding the durability life of the battery is secured and realized

- Information description

-

Description1~2 liquid type material including silicone/non-silicone resin and thermal conductive filler

-

UsePerforms the role of reducing the temperature of the hot parts in the electronic device

-

Application areasApplied between the battery cell, module and cooling parts in the electric vehicle

-

Main propertiesThermal conductivity, filling rate, adhesive strength and hardness, etc.

-

CharacteristicsManufacturing available in silicone/non-silicone types and 1~2K liquid type, and hardens at room temperature or high temperatures

-

Brand

-

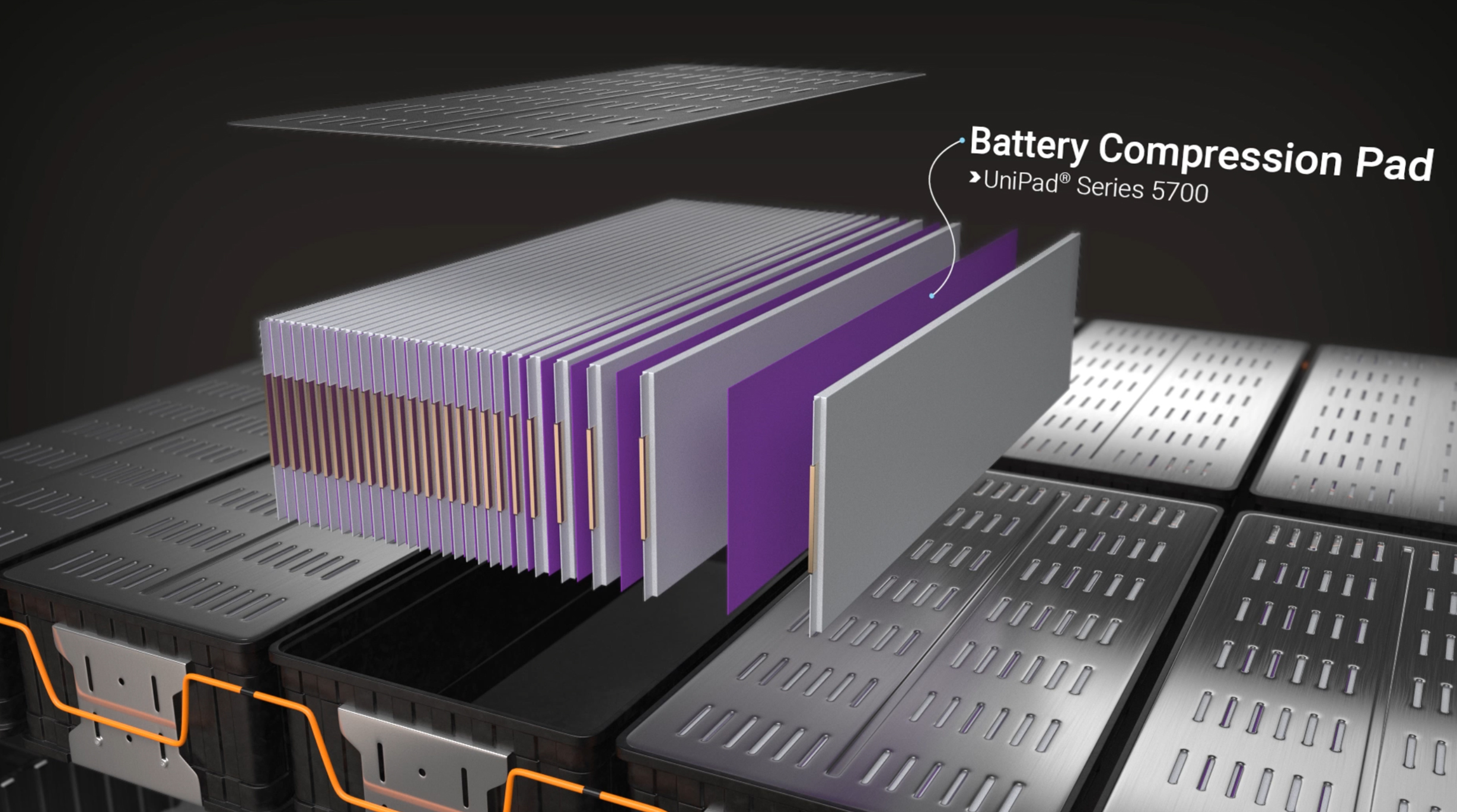

Battery Compression Pad

From ultra-low density to high-density battery compression pads, UniPad® supplementing the durability of the lithium-ion battery can be designed in the restitution performance that complies with battery characteristics

- Product characteristics

- Very similar restitution elasticity is realized in a wide range of compression levels

- Long-term maintenance of the material performance is available in various exposure environmental cycles according to the charging and discharging of the battery

- Fire-resistance level of UL-HBF or higher is met

- Information description

-

DescriptionProduct in open cell pad form, manufactured with polyurethane/silicone, etc.

-

UseComponent for improving the durability of the battery cell by applying fixed pressure to the contraction and swelling according to the use of the battery cell

-

Application areasApplied between the pouch-type battery cells on electric vehicles

-

Main propertiesCompression Force Deflection, Density, Flammability, Compression set

-

CharacteristicsPolyurethane base, Pad type

-

Brand

-

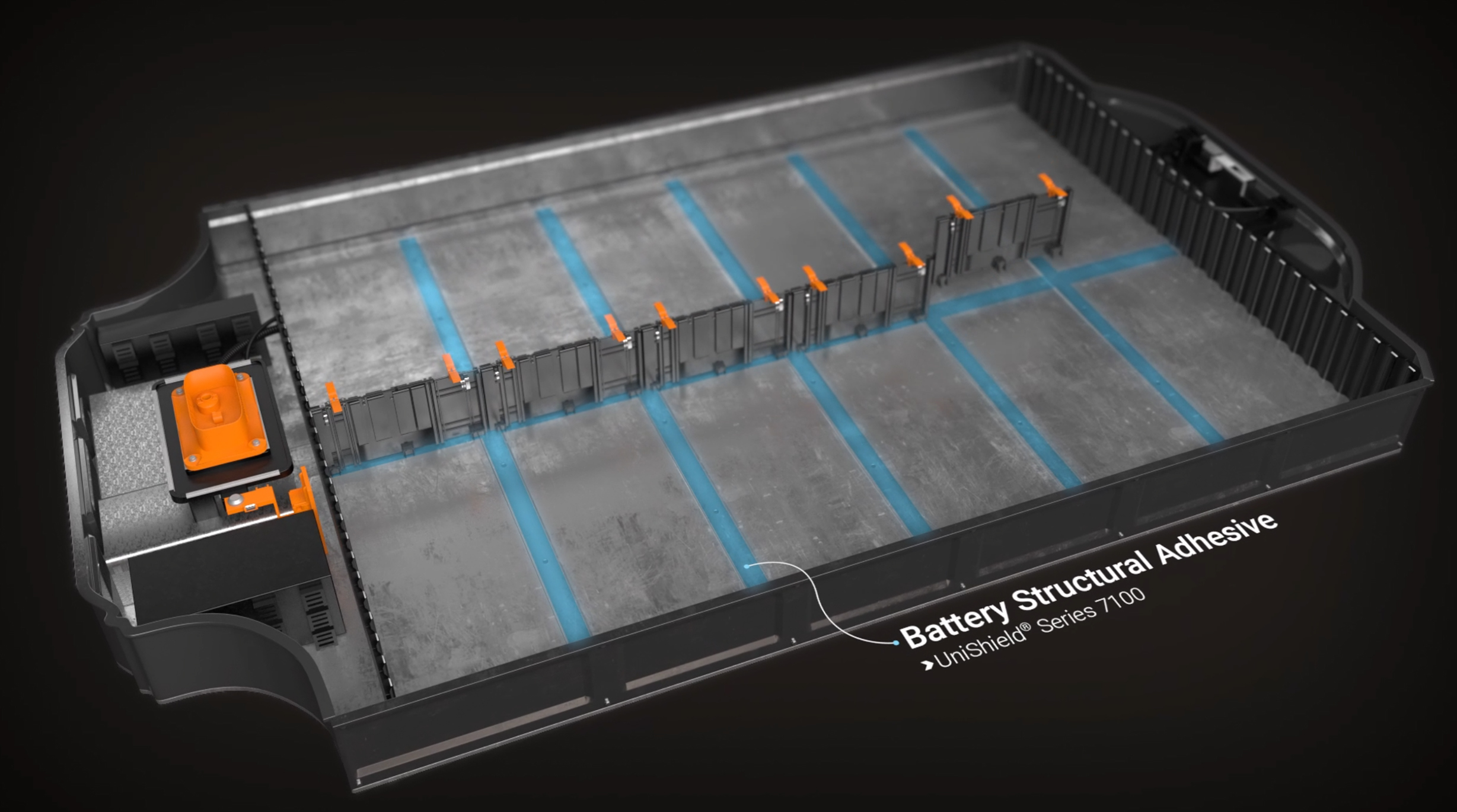

Battery Structural Adhesive

With high durability and stiffness, UNITECH’s structural adhesive increases the convenience in production of battery modules

- Product characteristics

- The role of the structural adhesive on absorbing the impact in low and high temperature environment is realized in the battery system as well

- Products added with the 1~2 liquid-type solutions and special functions are available to meet the requirements of the customer’s process request

- UNITECH carries multiple products certified with Global Automotive OEM approval

- Information description

-

DescriptionStructural adhesive applied to the transportation method or battery system structure components to absorb the impact on emergencies to improve the stability of the system

-

UseAdhesion or substitution of welding on the structural components of the vehicle battery pack, or between different materials

-

Application areasStructural components, etc. for absorbing the impact on the battery pack structure and tray, etc.

-

Main propertiesShearing strength, impact strength, modulus and fatigue-resistance strength, etc.

-

CharacteristicsEpoxy, polyurethane, 1~2 liquid type, thermosetting or room-temperature setting type

-

Brand

-

Battery Housing Sealant

A product that seals the battery pack housing effectively from moisture, dust and foreign substances, etc., realizing top-notch performance by using various materials such as urethane, silicone, rubber, PVC and epoxy, etc.

- Product characteristics

- Appropriate selection is possible on the various chemical materials complying with the stiffness required by the customer

- World’s highest level of sealing performance proven in the automotive, aerospace and LNG carrier industries (water-tightness/air-tightness, etc.)

- Smooth adhesive performance is realized in various applying materials, and environmental durability up to 30 years is possible

- Information description

-

DescriptionSealant used for sealing the battery pack/housing

-

UseComplete isolation of moisture or foreign substances from the battery pack

-

Application areasJoint between the battery housing and cover, and parts in the design that require sealing

-

Main propertiesShear strength, elongation, specific gravity, airtightness and moisture absorption rate, etc.

-

Characteristics1~2 liquid type, room-temperature of high-temperature setting type such as Polyurethane, Silicone, Rubber, PVC and epoxy, etc.

-

Brand

FAQ

Contact Us- What makes UNITECH’s thermal adhesives better than competing products?Our products are unrivalled in terms of durability, maintaining performance for extended periods of time even when extreme environments repeatedly occur.

- What companies use UNITECH battery solutions?Domestic and foreign companies leading the battery and system market, and Korean, European and US auto-makers are currently in joint development with us and are using our products.

- What other products can be developed aside from the products indicated above?With a clear technological goal from the customer, anything is possible.

- What are the countries that can use the products developed by UNITECH?Products of UNITECH are developed from the initial stage for overseas use. From the selection of raw materials, TSCA (USA), REACH (Europe) and chemical inventory of various countries are reviewed in detail to prevent any issues in manufacturing and exporting.