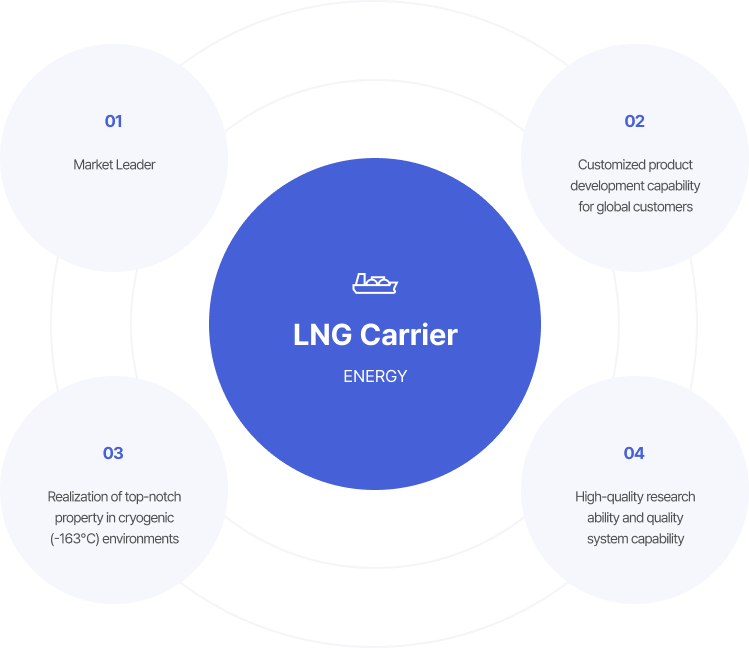

LNG Carrier

UNITECH, No. 1 LNG carrier adhesives leader,

provides best solutions.

Overview of LNG carrier business

As the use of LNG, an eco-friendly fuel, is

increasing globally, the LNG carrier market is

expanding continuously.

Based on its professional technology accumulated

over 20 years, UNITECH supplies products to the

customers that are uniform, reliable and of high

quality.

UNITECH will continue developing market-leading

products to provide a next level eco-friendly

solution.

- LNG usage

- LNG carrier market

- Shipbuilding adhesiv

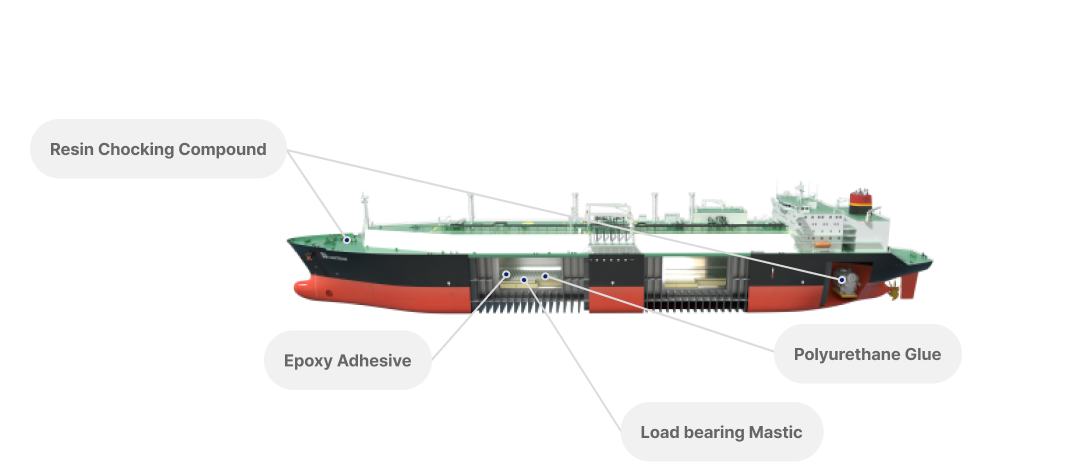

LNG carrier business solution

UNITECH possesses the main adhesive groups used in manufacture of cargo tank on the LNG carriers, and customers can establish a one-stop supply chain. Based on the high level of technology and know-how on the adhesives, UNITECH provides the most appropriate solution for the customer site.

Supply Chain

Technology & know-how

Capabilities

Product

-

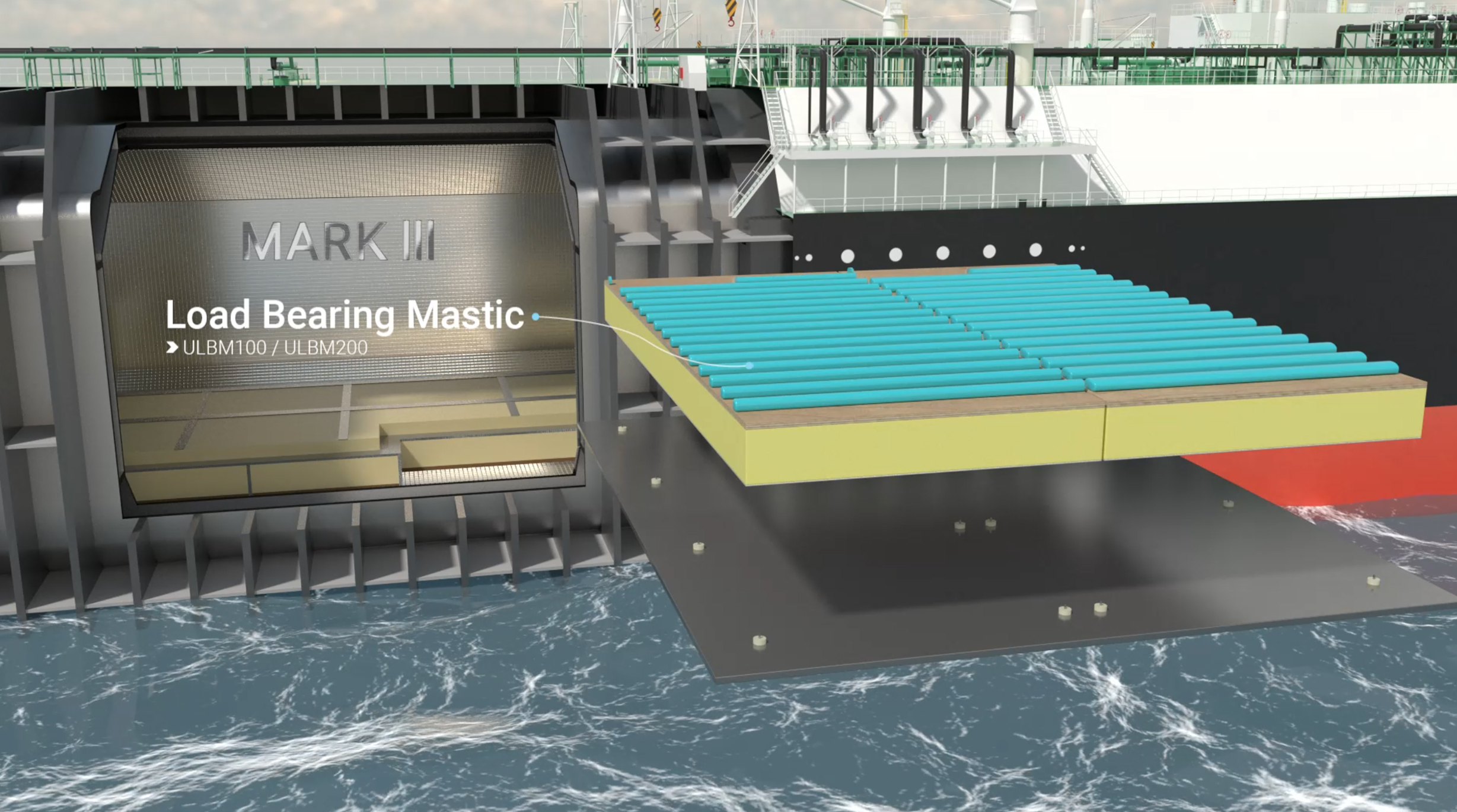

Load Bearing Mastic

Adhesives for insulating materials in the LNG carrier cargo tank

- Product Characteristics

- Used in body and insulating material adhesion and filling

- Endures large loads by equally distributing the weights

- Possessing various mastics applicable to different technologies

- Brand

- ULBM® Series

-

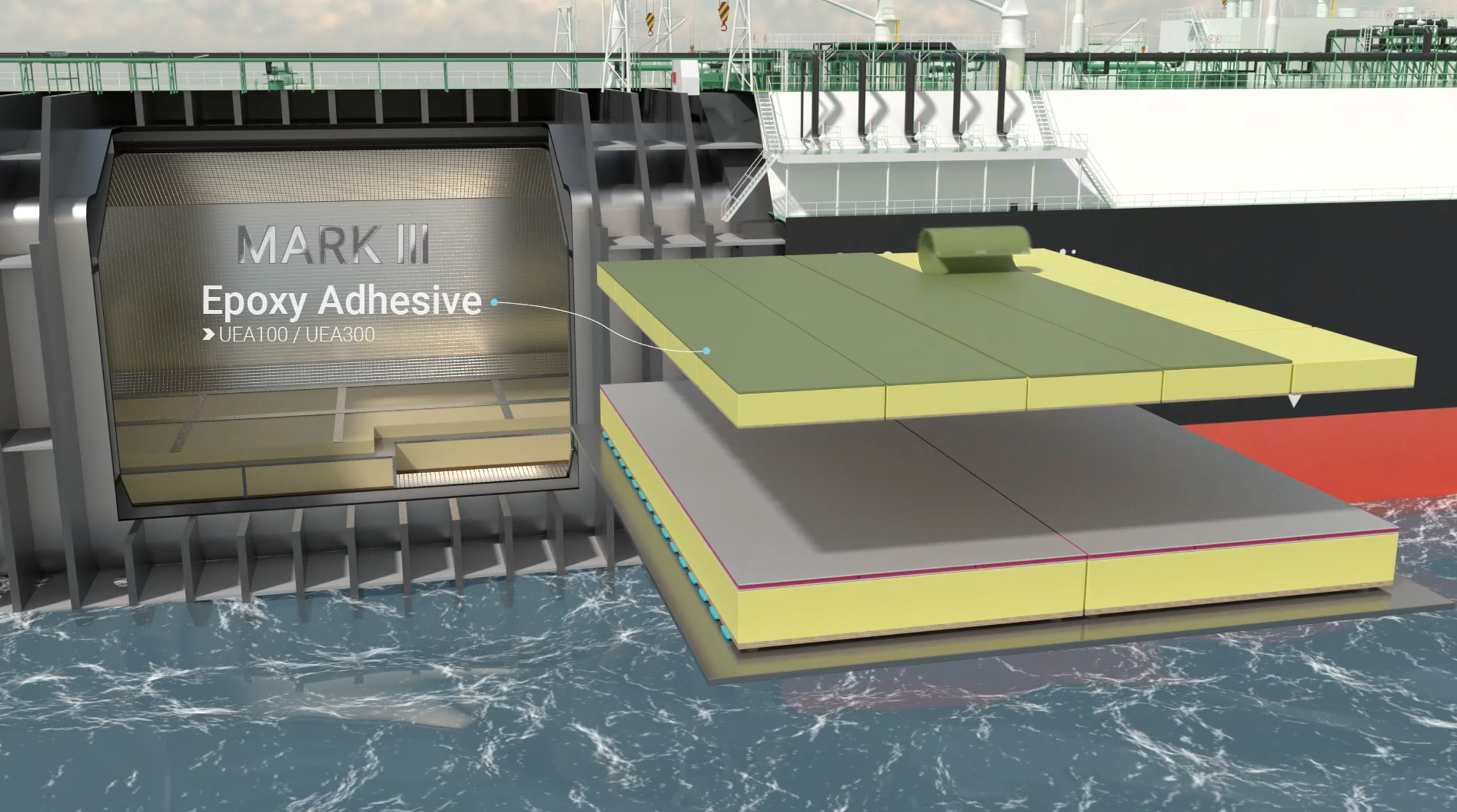

Epoxy Adhesive

Composite material adhesives in the LNG carrier cargo tank

- Product Characteristics

- Outstanding property displayed even in cryogenic environments

- Used in adhesion between composite materials and adhesion of the composite materials and the insulating materials

- Brand

- UEA® Series

-

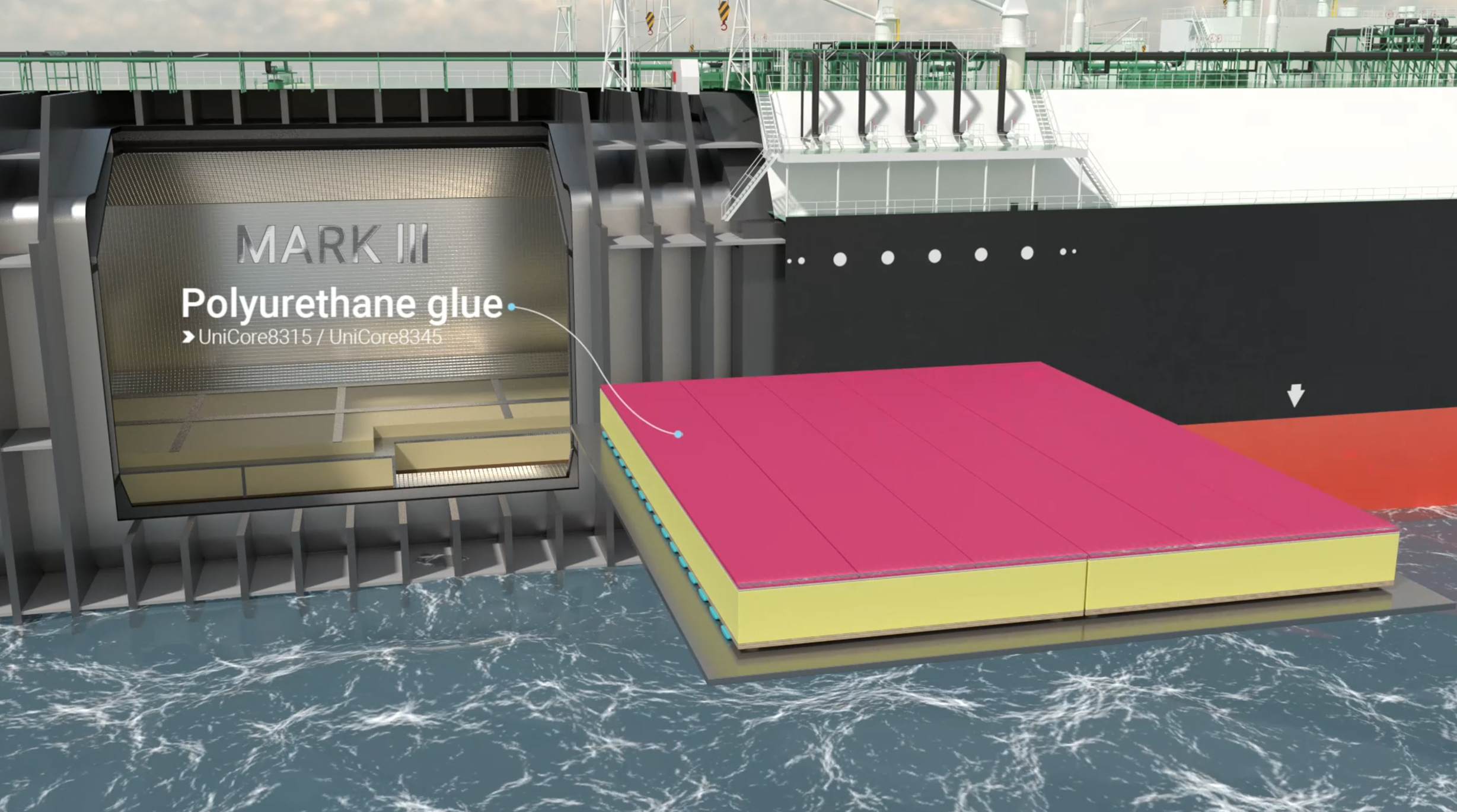

Polyurethane Glue

Composite material adhesive in the LNG carrier cargo tank

- Product Characteristics

- Used for secondary barrier adhesion

- Outstanding adhesion

- Two models - automatic and manual

- Brand

- UniCore®

-

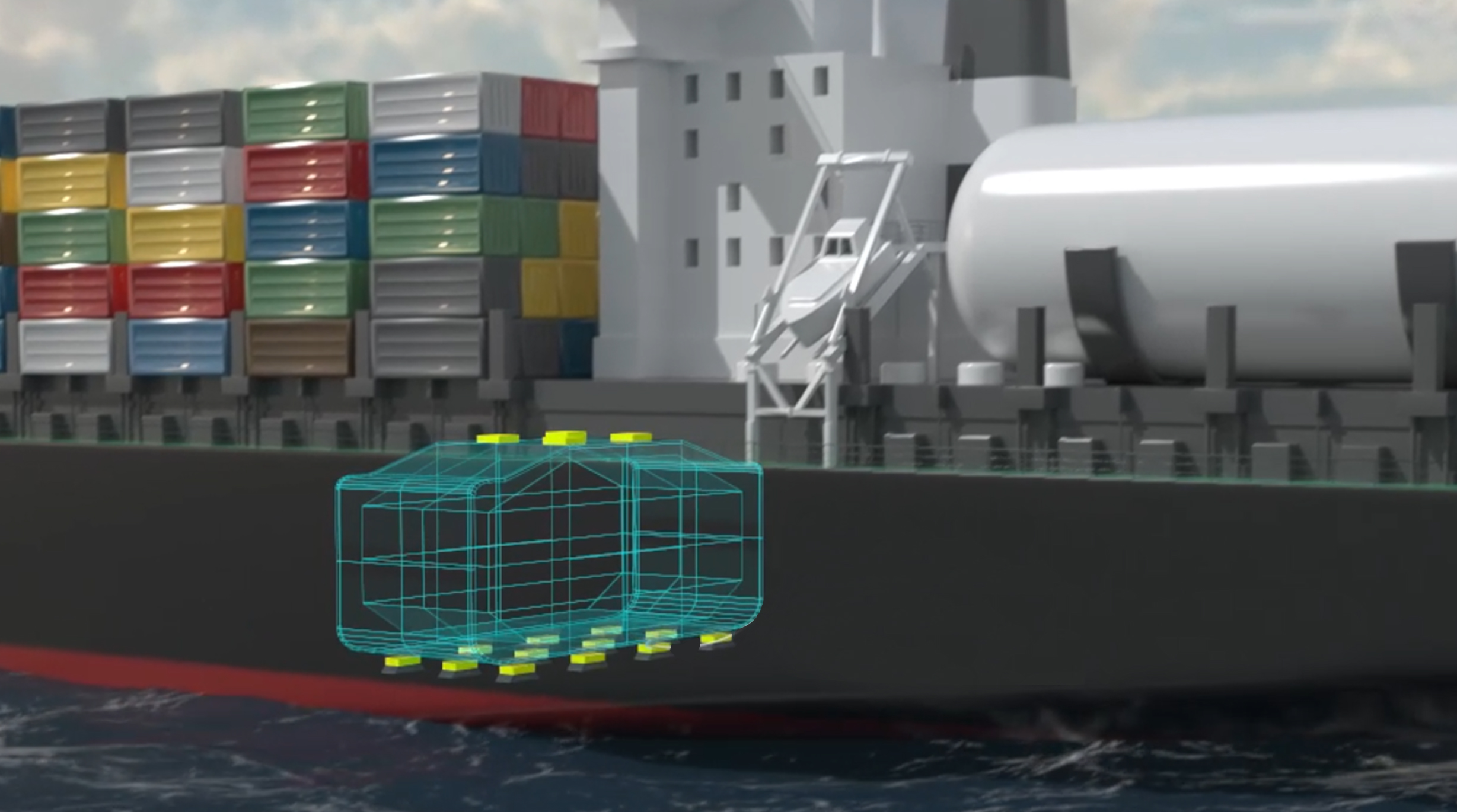

Resin Chocking Compound

Epoxy resin for foundation and alignment of mechanical equipment and heavy load items

- Product Characteristics

- Outstanding flowability. Occurrence of crack is minimized

- Unsophisticated working condition, and convenience in workability

- Brand

- UniChock, UniCore®

-

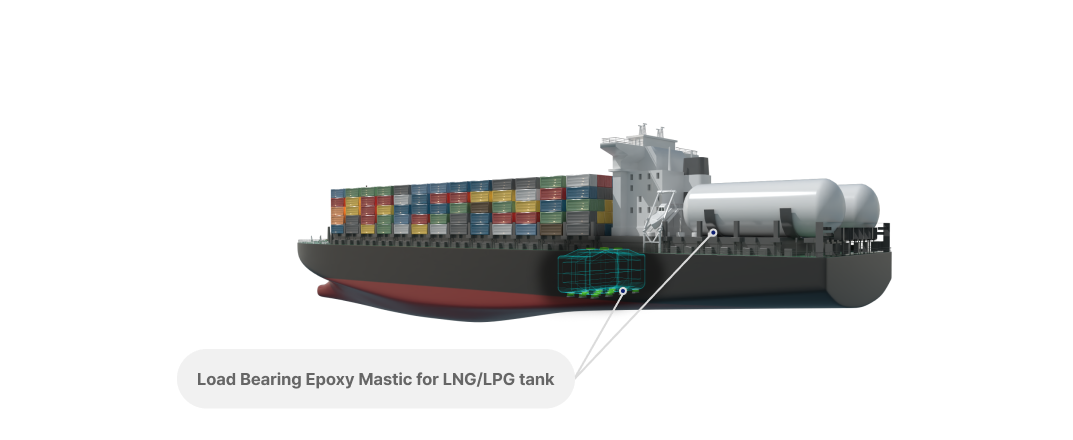

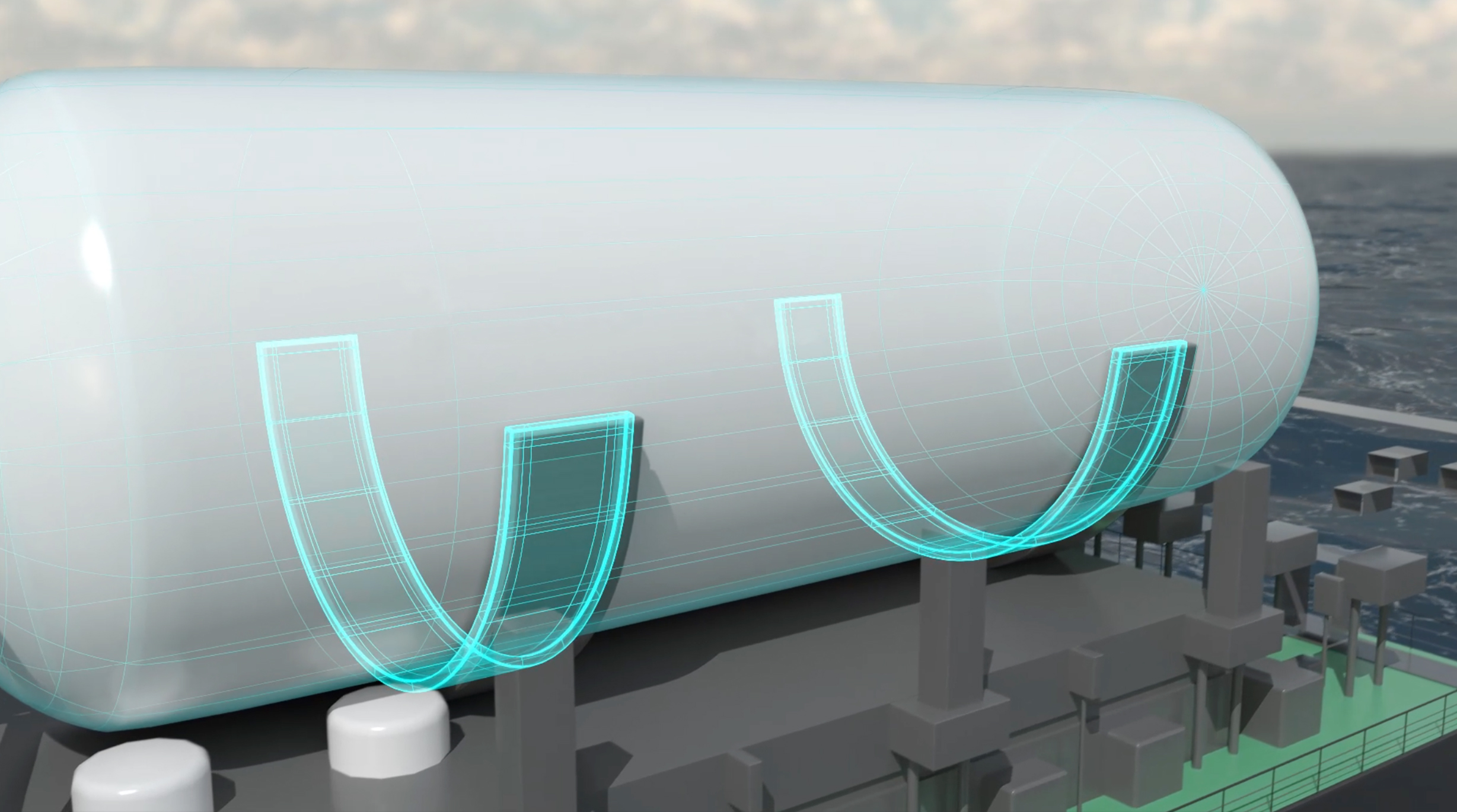

Load Bearing Epoxy Mastic for LNG/LPG tank

IMO B&C type Cryogenic LNG/LPG tank supporting epoxy resin

- Product Characteristics

- Outstanding adhesiveness and compression level in cryogenic (-196℃) environments

- Excellent workability (LQ: High Flowability, PT: Low Droopiness)

- Unsophisticated working conditions (long pot life)

- Brand

- UniCore 8480 LQ (Liquid Type), UniCore 8480 PT (Paste Type)

FAQ

Contact Us- Where can I find the details on the product?The staff in charge will attend to inquiries when a customer inquiry is submitted through the notice board.

- How can I request for the development of a new product?Please inform us the detailed application of use and purpose, etc., and application of existing products and feasibility of development will be reviewed.

- Where are the manufacturing plants located?All products related to vessels are currently produced in the headquarters located in Korea. If required, products can also be manufactured in Europe, USA and China.

- What are the advantages of UNITECH products?As the leading company in the global market, advantages of UNITECH products include top quality and competitive price.